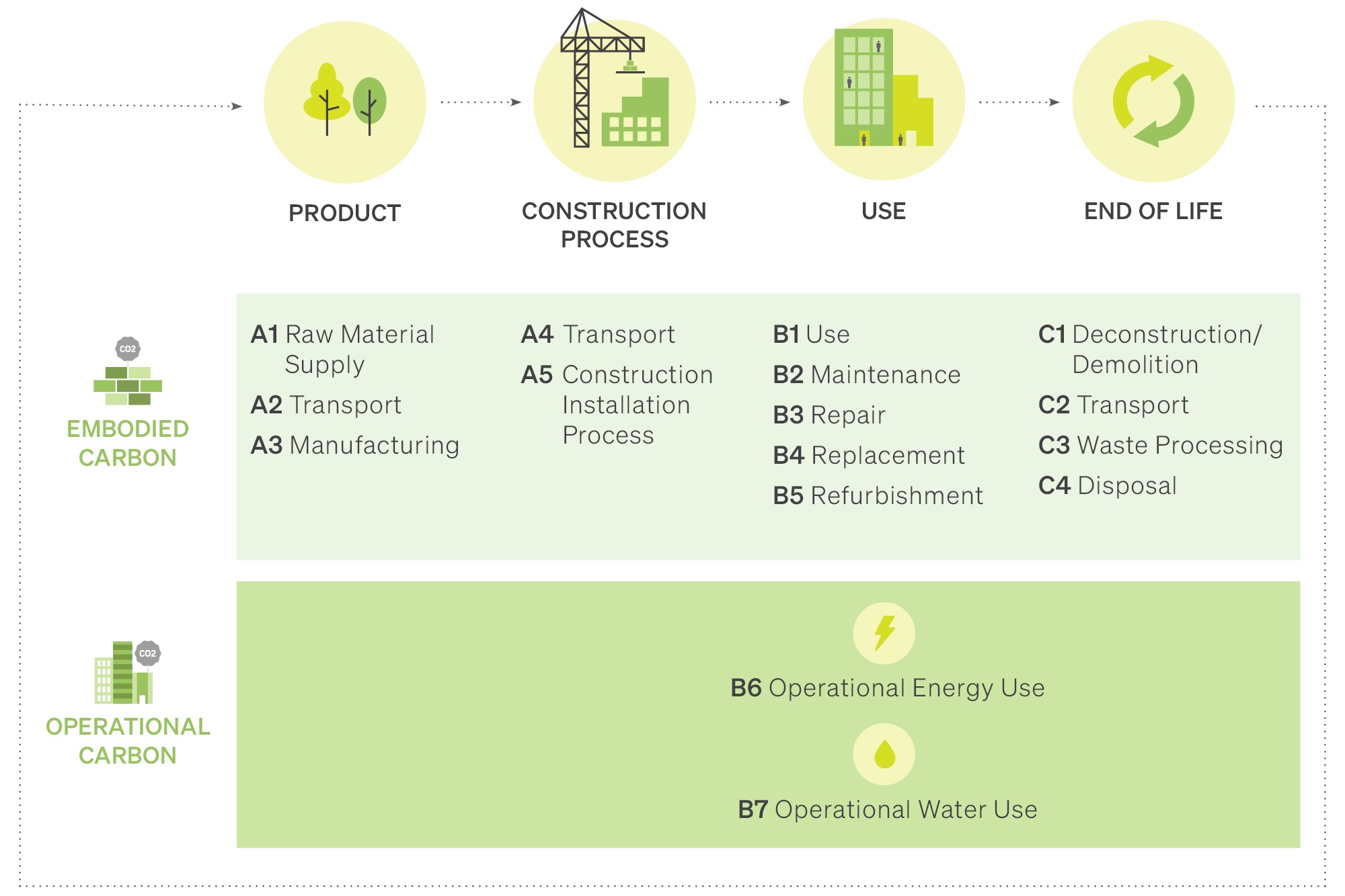

Ayers Saint Gross has long embraced sustainability as a vital component of good design. We believe the more research we perform and the more data we collect, the greater our ability is to achieve ambitious sustainability goals and design beautiful and functional buildings for our clients. We have focused our thinking about building performance into two categories: embodied carbon and operational carbon.

We utilize Whole Building Life Cycle Assessments (WBLCA) to investigate the impact and opportunities of construction materials and products to achieve our embodied carbon reduction goals. WBLCA looks at the environmental impacts of building materials (including global warming potential) over their entire life cycle — from extraction and manufacturing through the landfill or recycling plant.

We are calculating the embodied carbon of completed projects to identify which components or life cycle stages are the largest contributors to environmental impact, and will leverage this information to inform even stronger design processes in the future.

One project we’ve completed a WBLCA on is the Hayden Library Reinvention. By renovating existing buildings in lieu of tearing them down and constructing with new materials, we avoid the embodied carbon of new construction altogether. WBLCA was conducted to quantify how much embodied carbon was preserved by maintaining 95% of the building’s existing opaque envelope and structural system and how much additional embodied carbon was invested to make the building useful for the next 50+ years. Our analysis revealed 9000 MT of CO2e was preserved in the renovation while only another 550 MT of CO2e were spent. This example illustrates how building renovation or reuse can greatly reduce construction’s embodied carbon impact.

Structural systems and building envelopes tend to be significant sources of embodied carbon. For Semans-Griswold Environmental Hall, we found that we could substantially reduce environmental impact by focusing on the materials chosen for curtainwall systems because of aluminum’s high embodied carbon. Similarly, focusing on thermal insulation also helped us reduce embodied carbon because some types of foam insulation, including expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate or spray foam insulation, have blowing agents with massive global warming potential. Specifying insulation materials with lesser embodied carbon can be helpful in reducing impact.

Reducing embodied carbon in construction requires collaboration between designers, builders, structural engineers, and manufacturers across the building sector. WBLCA during the various design stages can be helpful in making choices between various building structural systems, assemblies, and products. We look forward to continued engagement with our partners to reach our embodied carbon reduction goals.

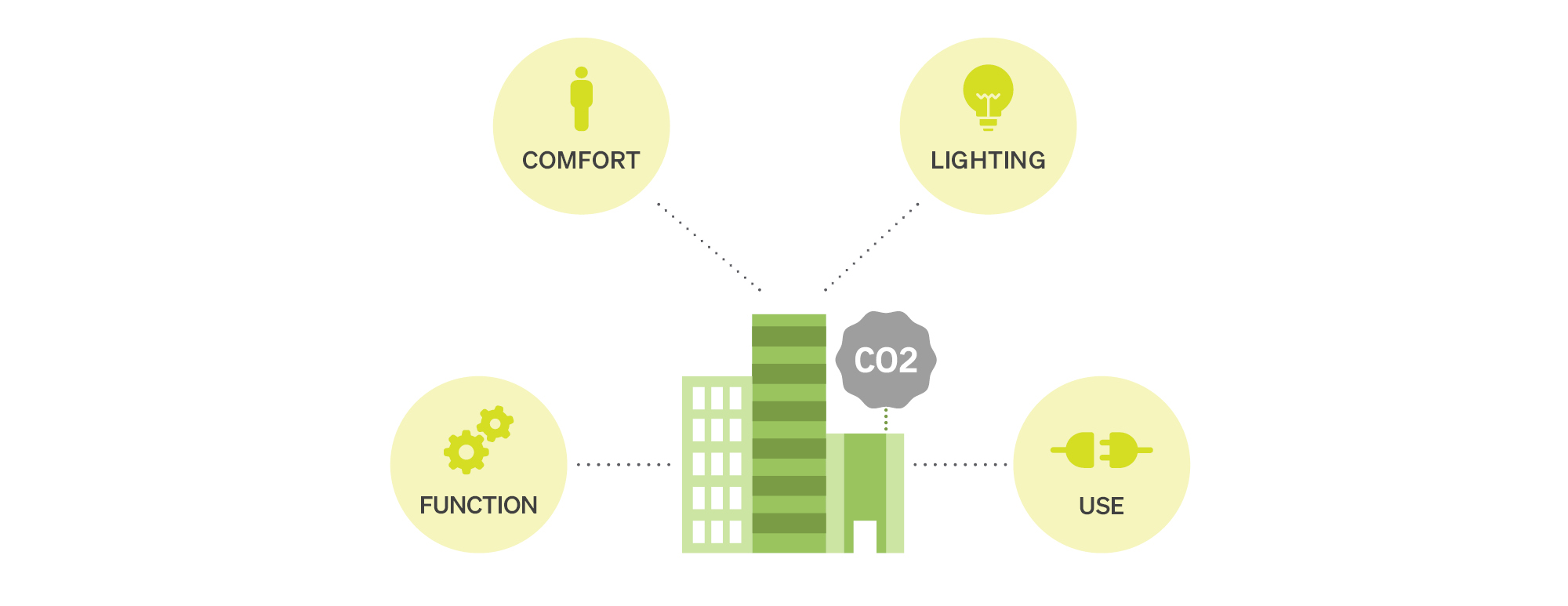

While embodied carbon has more recently come to the forefront of sustainability discussions in the AEC industry, operational carbon (which occurs during the in-use phase of a building) has been the primary focus of sustainability thinking over the last several decades. Our thinking on operational carbon has continuously evolved during that time. We are developing in-house digital tools and systems for measuring operational carbon throughout the design process so that we can produce buildings that function better, cost less to operate, and are better aligned with our clients’ sustainability goals.

To reduce operational carbon in buildings, Ayers Saint Gross has been developing a process of iterative performance analysis throughout the design process. From early-stage climate analysis to understand site factors such as temperature, humidity, and solar access, to whole building energy models, we rely on thoroughly tested analysis tools and robust data to predict how buildings will perform prior to starting construction.

One of our most versatile methods for understanding building performance is known as “shoebox analysis.” By taking a simple, repeating element of the building (e.g., a single structural bay), we can run quick analyses on a small area but learn a lot about a large area of the building design.

We use this type of analysis to quickly learn about holistic effects of small design changes. For example, we can create a model with a small window and a large window in a repeated office module or student housing unit and compare how the variation in window size affects daylight access, outdoor view access, solar heat gain, thermal comfort, glare potential, and expected energy usage intensity (EUI). Since these models are small, we can run analyses in a fraction of the time of larger models and extrapolate the results to how a whole building is likely to perform.

The shoebox analysis is part of a larger toolkit developed by Ayers Saint Gross to evaluate expected building performance. These tools allow us to better study occupant comfort by visualizing more analytical and sensorial aspects of a building such as daylight access and thermal comfort. These tools provide a fast, reliable way for our design teams to optimize a building, saving owners money in both up-front and operational costs.

We’re excited to continue advancing strategies toward carbon neutrality. The tools we’re leveraging to optimize embodied carbon investments and reduce operational carbon will help us in aligning the people, programs, and places we serve to champion environmental stewardship, healthy living, and positive social and economic outcomes for all.